Chemical Process Design Software

83 rows This is a list of software used to simulate the material and energy balances of chemical processing plants. Apr 03, 2017 Some of the other leading Chemical Process Design companies include Technip, Saipem, Dow, Toyo, Linde, Lurgi, Stamicarbon, Lummus, Air Liquide, Uhde etc where Chemical Engineers have enormous opportunities to work with. Hope this will help Chemical Engineers to land their dream job in Chemical Process design companies.

- Chemical Process Design Software For Pc

- Chemical Process Design Book

- Industrial Chemical Process Design

- Chemical Process Simulation Software

| Part of a series on |

| Chemical engineering |

|---|

| Fundamentals |

| Unit processes |

| Aspects |

|

| Glossaries |

| Category |

- Jul 18, 2014 Process simulation software (e.g. HYSYS, AspenPlus, PRO/II) is widely-used across the industry to model steady-state or dynamic processes and to conduct studies. MATLAB seems to be popular for numerical computation. Control systems use specializ.

- Process and Instrumentation Drawing Software Help draw process and instrumentation diagrams with rich examples and standard P&ID symbols. Edraw allows you to more easily create piping and instrumentation diagrams for piping systems, industrial, chemical, fluids and hydraulics drawings.

- Find and compare Chemical software. Free, interactive tool to quickly narrow your choices and contact multiple vendors. Essential software toolkit for process research, development, design, and digitalization, as well as for estimating process efficiencies, yields, and environmental footprints.

This is a list of software used to simulate the material and energy balances of chemical processing plants.

| Software | Developer | Applications | Operative system | License | URL |

|---|---|---|---|---|---|

| Advanced Simulation Library | Avtech Scientific | Process data validation and reconciliation, real-time optimization, virtual sensing and predictive control | Windows, Linux, FreeBSD, Mac | open-source | [1] |

| APMonitor | Data reconciliation, real-time optimization, dynamic simulation and nonlinear predictive control | [2] | |||

| Apros | Fortum and VTT Technical Research Centre of Finland | Dynamic process simulation for power plants | Windows | Commercial | [3] |

| Aspen Plus | Aspen Technology | Process simulation and optimization | Windows | Commercial | [4] |

| Aspen HYSYS | Aspen Technology | Process simulation and optimization | Windows | Commercial | [5] |

| ASSETT | Kongsberg Oil & Gas Technologies AS | Dynamic process simulation | [6] | ||

| BatchColumn | ProSim | Simulation and Optimization of batch distillation columns | Windows | commercial | [7] |

| BATCHES | Batch Process Technologies, Inc. | Simulation of recipe driven multiproduct and multipurpose batch processes for applications in design, scheduling and supply chain management | Linux | Commercial | [8] |

| BatchReactor | ProSim | Simulation of chemical reactors in batch mode | Windows | commercial | [9] |

| D-SPICE | Kongsberg Oil & Gas Technologies AS | ||||

| K-Spice | Kongsberg Oil & Gas Technologies AS | Dynamic process simulation and multiphase pipeline simulation | [10] | ||

| CADSIM Plus | Aurel Systems Inc. | Steady-state and dynamic process simulation | [11] | ||

| ChromWorks | YPSO-FACTO | Chromatographic process design, simulation & optimization | [12] | ||

| CHEMCAD | Chemstations | Software suite for process simulation | [13] | ||

| Cycad Process | CM Solutions | Process simulation and drawing package for minerals and metallurgical fields | Windows | Commercial, Free for academic use | [14] |

| Cycle-Tempo | Asimptote | Thermodynamic analysis and optimization of systems for the production of electricity, heat and refrigeration | [15] | ||

| COCO simulator | AmsterCHEM | Steady state simulation | free of charge | [16] | |

| Design II for Windows | WinSim Inc. | Process simulation | [17] | ||

| Distillation expert trainer | ATR | Operator training simulator for distillation process | [18] | ||

| DWSIM | Daniel Medeiros, Gustavo León and Gregor Reichert | Process simulator | Windows, Linux, macOS, Android, iOS | open-source (Windows/Linux/macOS), free + in-app purchases (Android/iOS) | [19] |

| DynoChem | Scale-up Systems | Dynamic process simulation and optimization | Windows | Commercial | [20] |

| EMSO | ALSOC Project | Modelling, simulation and optimisation, steady state and dynamic, equation oriented with open source models | Windows, Linux | ALSOC License | |

| EQ-COMP | Amit Katyal | Vapor Liquid Equilibrium Software | SAAS | [59] | |

| Dymola | Dassault Systèmes | Modelica-based dynamic modelling and simulation software | Windows, Linux | Commercial | [22] |

| Flowtran simulation | Monsanto | ||||

| gPROMS | PSE Ltd | Advanced process simulation and modelling | [23] | ||

| HSC Sim | Outotec Oyj | Advanced process simulation and modelling, Flowsheet simulation | Windows | [24] | |

| HYD-PREDIC | Amit Katyal | Flow Assurance Software | |||

| HYDROFLO | Tahoe Design Software | Piping System Design with Steady State Analysis | Windows | Free Academic -Std Commercial | [25] |

| Indiss Plus® | Corys | High-fidelity dynamic simulations for hydrocarbons, chemicals | [26] | ||

| ICAS: integrated computer-aided system | CAPEC | [27] | |||

| IDEAS | Andritz Automation | [28] | |||

| ITHACA | Element Process Technology | Dynamic chemical process simulator | Windows | [29] | |

| iiSE Simulator | iiSE company | Equation oriented chemical process simulator and optimizer | Windows, Linux | Freeware demo, Commercial | [30] |

| LIBPF | C++ LIBrary for process flowsheeting | ||||

| JModelica.org | Modelon AB | open-source | |||

| METSIM | Proware | General-purpose dynamic and steady state process simulation system | Windows | [31] | |

| Mimic Simulation Software | MYNAH Technologies | First-principles dynamic simulator built for software acceptance testing and operator training systems | |||

| Mobatec Modeller | Mobatec | Advanced Dynamic (Steady-State) Process Modelling Environment | Windows | [33] | |

| NAPCON ProsDS | Neste Engineering Solutions Oy | Dynamic process simulation | Windows | [34] | |

| Clearview | Mapjects | Dynamic Asset BIM process simulation and optimization | Windows & Debian Linux | ||

| OLGA | SPT Group (Schlumberger) | ||||

| OLI Analyzer | OLI Systems, Inc. | Chemical phase equilibrium simulation featuring electrolytes | Windows | Commercial | [35] |

| Omegaland | Yokogawa | ||||

| OptiRamp | Statistics & Control, Inc. | Real-time Process Simulation and Optimization, Multi variable Predictive Control | Windows | Commercial | [36] |

| OpenModelica | Open-Source Modelica Consortium | open-source | |||

| PIPE-FLO Professional | Engineered Software Inc. | Piping System Simulation and Design | Windows | Commercial | [37] |

| PEL Software Suite | |||||

| Petro-SIM | KBC Advanced Technologies | [38] | |||

| PETROX | Petrobras | General Purpose, Static, Sequential-Modular Process Simulator | Windows | internal users only | |

| Power Plant Simulator & Designer | KED GmbH | Basic Engineering and Dynamic process simulation for power plants | Windows | Commercial | [39] |

| Process Studio | Protomation | Simulation Suite for Modeling, Engineering & Training | Windows | Commercial | [40] |

| Prode Properties | Prode Software | Thermodynamic Library, Properties of pure fluids and mixtures, Multi phase Equilibria + process simulation | Windows, Linux, Android | Free version + commercial versions | [41] |

| Prode simulator | Prode Software | Process Simulator | Windows | commercial | [42] |

| ProPhyPlus | ProSim | Thermodynamic calculation software | Windows | commercial | [43] |

| ProSec | ProSim | Simulation of brazed plate fin heat exchangers | Windows | commercial | [44] |

| ProSim DAC | ProSim | Dynamic adsorption column simulation | Windows | commercial | [45] |

| ProSim HEX | ProSim | Heat Exchangers Simulation | Windows | commercial | [46] |

| ProSimPlus | ProSim | Steady-state simulation and optimization of processes | Windows | commercial | [47] |

| ProSimulator | Sim Infosystems | Process and Power plant simulation | Windows | [48] | |

| Pro-Steam | KBC Advanced Technologies | ||||

| ProMax | Bryan Research & Engineering | Process simulator capable of modeling oil & gas plants, refineries, and many chemical plants | Windows | [49] | |

| ProMax / TSWEET | Bryan Research & Engineering | Retired process simulators now incorporated in ProMax | |||

| PRO/II | SimSci | [50] | |||

| DYNSIM | SimSci | ||||

| ROMeo (process optimizer) | SimSci | ||||

| RecoVR | VRTech | ||||

| REX | Optience | Reactor Optimization and Kinetic Estimation | Windows | [51] | |

| Simulis Thermodynamics | ProSim | Mixture properties and fluid phase equilibria calculations | commercial | [52] | |

| SimCreate | TSC Simulation | Real time, first principle and generic operator training simulations, plant specific emulations and OPC for live plant connections. | Windows | Commercial | [53] |

| SimCentral | SimSci | Steady state, Fluid flow and Dynamic process simulator. | [54] | ||

| SPEEDUP | Roger W.H. Sargent and students | ||||

| SolidSim (Now in Aspen Plus) | SolidSim Engineering GmbH | Flowsheet simulation of solids processes | [55] | ||

| SuperPro Designer | Intelligen | [56] | |||

| SysCAD | KWA Kenwalt Australia | Process simulation | Windows | [57] | |

| System7 | Epcon International | [58] | |||

| UniSim Design Suite | Honeywell | Process simulation and optimization | Windows | Commercial and Academic | [59] |

| UniSim Competency Suite | Honeywell | Opertator Competency Management and Training | Windows | Commercial and Academic | [60] |

| Usim Pac | Caspeo | Steady-state simulator for the mineral industry, biorefineries and waste treatment | Windows | Commercial | [61] |

| Virtuoso | Wood Group | Multiphase dynamic process simulator for oil & gas production | Windows | Commercial | [62] |

| VMGSim | Virtual Materials Group | [63] | |||

| Wolfram SystemModeler | Wolfram Research | Windows, Mac, Linux | [64] |

See also[edit]

References[edit]

- Seader, J.D., Seider, W.D. and Pauls, A.C.: Flowtran Simulation – An Introduction, 2nd Edition, CACHE (1977).

- Douglas, J.M.: Conceptual Design of Chemical Processes, McGraw-Hill, NY, USA (1988).

- Smith, R., Chemical process Design and Integration, Wiley, Chichester, UK (2005).

- Seader, W.D., Seider, J.D., Lewin, D.R. and Widagdo, S. Product and Process Design Principles Synthesis, Analaysis and Design, 3rd Ed., Wiley, Hoboken, NJ, USA (2009)

| Part of a series on |

| Chemical engineering |

|---|

| Fundamentals |

| Unit processes |

| Aspects |

|

| Glossaries |

| Category |

In chemical engineering, process design is the choice and sequencing of units for desired physical and/or chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components.

Process design can be the design of new facilities or it can be the modification or expansion of existing facilities. The design starts at a conceptual level and ultimately ends in the form of fabrication and construction plans.

Chemical Process Design Software For Pc

Process design is distinct from equipment design, which is closer in spirit to the design of unit operations. Processes often include many unit operations.

Documentation[edit]

Process design documents serve to define the design and they ensure that the design components fit together. They are useful in communicating ideas and plans to other engineers involved with the design, to external regulatory agencies, to equipment vendors and to construction contractors. Replace generic pnp monitor driver.

In order of increasing detail, process design documents include:

- Block flow diagrams (BFD): Very simple diagrams composed of rectangles and lines indicating major material or energy flows.

- Process flow diagrams (PFD): Typically more complex diagrams of major unit operations as well as flow lines. They usually include a material balance, and sometimes an energy balance, showing typical or design flowrates, stream compositions, and stream and equipment pressures and temperatures.

- Piping and instrumentation diagrams (P&ID): Diagrams showing each and every pipeline with piping class (carbon steel or stainless steel) and pipe size (diameter). They also show valving along with instrument locations and process control schemes.

- Specifications: Written design requirements of all major equipment items.

Process designers typically write operating manuals on how to start-up, operate and shut-down the process. They often also develop accident plans and projections of process operation on the environment.

Documents are maintained after construction of the process facility for the operating personnel to refer to. The documents also are useful when modifications to the facility are planned.

A primary method of developing the process documents is process flowsheeting.

Design considerations[edit]

Chemical Process Design Book

There are several considerations that need to be made when designing any chemical process unit. Design conceptualization and considerations can begin once product purities, yields, and throughput rates are all defined.

Objectives that a design may strive to include:

- Throughput rate

- Product purity

Constraints include:

Industrial Chemical Process Design

- Capital cost: the amount of budget or investment to construct end to end process.

- Available space: the area of the land to build the plant.

- Safety concerns: consideration towards risk analysis on industrial accidents or hazardous chemicals.

- Environmental impact and projected effluents and emissions

- Waste production/recycling: manage waste produced as side product of the process for not to harm the surroundings.

- Operating and maintenance costs: represent the variable cost of the operational of the plant.

Other factors that designers may include are:

- Flexibility

- Anticipated variability in feed stock and allowable variability in product.

Chemical Process Simulation Software

Sources of design information[edit]

Designers usually do not start from scratch, especially for complex projects. Often the engineers have pilot plant data available or data from full-scale operating facilities. Other sources of information include proprietary design criteria provided by process licensors, published scientific data, laboratory experiments, and suppliers of feedstocks and utilities.

Design process[edit]

Design starts with process synthesis - the choice of technology and combinations of industrial units to achieve goals. More detailed design proceeds as other engineers and stakeholders sign off on each stage: conceptual to detailed design.

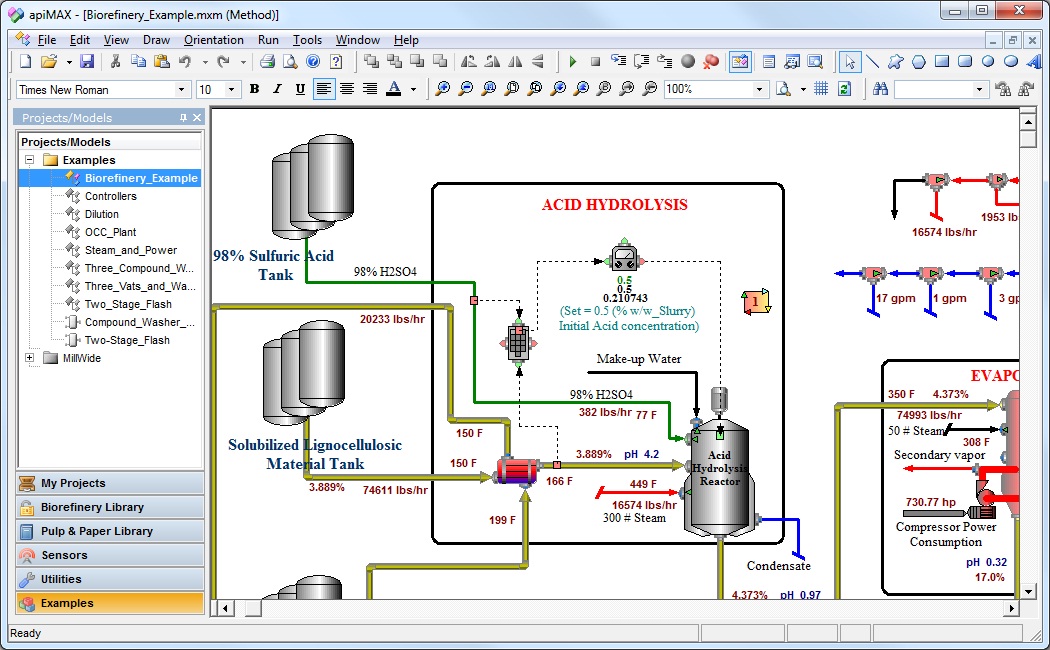

Simulation software is often used by design engineers. Simulations can identify weaknesses in designs and allow engineers to choose better alternatives. However, engineers still rely on heuristics, intuition, and experience when designing a process. Human creativity is an element in complex designs.

See also[edit]

Recommended chemical engineering books[edit]

- Sinnott and Towler (2009). Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design (5th ed.). Butterworth-Heinemann. ISBN0750685514.

- Moran, Sean (2015). An Applied Guide to Process and Plant Design (1st ed.). Butterworth-Heinemann. ISBN0128002425.

- Moran, Sean (2016). Process Plant Layout (2nd ed.). Butterworth-Heinemann. ISBN012803355X.

- Kister, Henry Z. (1992). Distillation Design (1st ed.). McGraw-Hill. ISBN0-07-034909-6.

- Perry, Robert H. & Green, Don W. (1984). Perry's Chemical Engineers' Handbook (6th ed.). McGraw-Hill. ISBN0-07-049479-7.

- Bird, R.B., Stewart, W.E. and Lightfoot, E.N. (August 2001). Transport Phenomena (Second ed.). John Wiley & Sons. ISBN0-471-41077-2.CS1 maint: multiple names: authors list (link)

- McCabe, W., Smith, J. and Harriott, P. (2004). Unit Operations of Chemical Engineering (7th ed.). McGraw Hill. ISBN0-07-284823-5.CS1 maint: multiple names: authors list (link)

- Seader, J. D. & Henley, Ernest J. (1998). Separation Process Principles. New York: Wiley. ISBN0-471-58626-9.

- Chopey, Nicholas P. (2004). Handbook of Chemical Engineering Calculations (3rdEdition ed.). McGraw-Hill. ISBN0-07-136262-2.

- Himmelbau, David M. (1996). Basic Principles and Calculations in Chemical Engineering (6th ed.). Prentice-Hall. ISBN0-13-305798-4.

- Editors: Jacqueline I. Kroschwitz and Arza Seidel (2004). Kirk-Othmer Encyclopedia of Chemical Technology (5th ed.). Hoboken, NJ: Wiley-Interscience. ISBN0-471-48810-0.CS1 maint: extra text: authors list (link)

- King, C.J. (1980). Separation Processes (2nd ed.). McGraw Hill. ISBN0-07-034612-7.

- Peters, M. S. & Timmerhaus K. D. (1991). Plant Design and Economics for Chemical Engineers (4th ed.). McGraw Hill. ISBN0-07-100871-3.

- J. M. Smith, H. C. Van Ness and M. M. Abott (2001). Introduction to Chemical Engineering Thermodynamics (6th ed.). McGraw Hill. ISBN0-07-240296-2.